澳大利亚国防科学与技术集团(DSTG)利用先进的 MTS 控制技术和基于模型的工程专业知识,加速对高度复杂且动态的直升机机体进行测试。

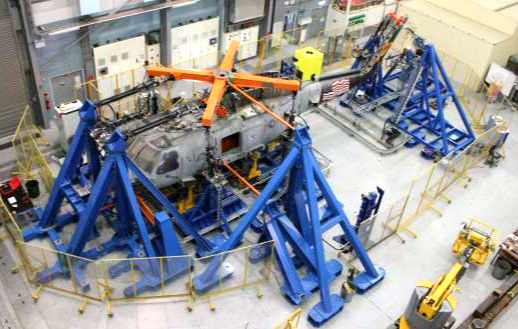

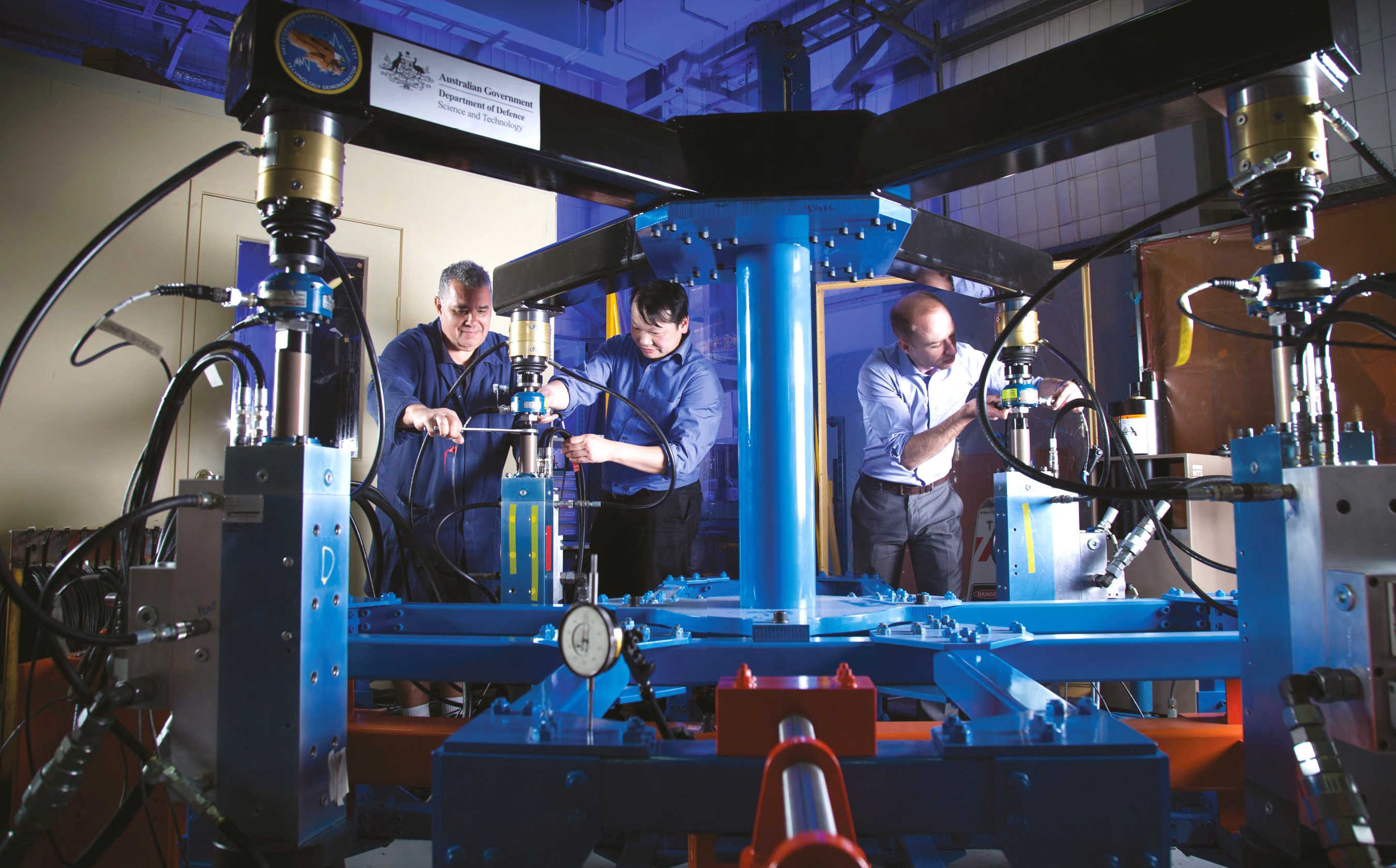

澳大利亚国防科学与技术集团(DSTG)的研究人员成功完成了一项为期六年的工作,建造了一个原型试验台,能够在加速时间内执行直升机机体的全尺寸疲劳试验(FSFT),其速度可与固定翼飞机测试相媲美。该项目被称为直升机先进疲劳试验–技术示范(HAFT-TD)计划,旨在开发方法,使全尺寸直升机试验件能够在 2.5 年或更短时间内承受相当于两个使用寿命周期的动态飞行载荷。为了降低风险、定制并整合实现项目目标所需的多种技术,DSTG 与澳大利亚皇家海军(RAN)、美国海军(USN)、默瑟工程研究中心(MERC)以及 MTS 系统建立了合作关系。

模型辅助补偿 (MAC)

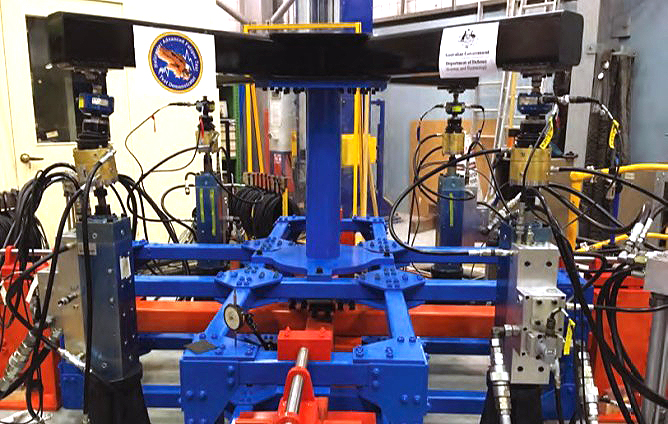

为了开发一个能够满足 HAFT-TD 所需的加速循环速率、高精度和多自由度要求的控制系统,DSTG 与 MTS 工程师合作,开发了一种用于伺服液压执行的先进模型辅助控制方法。模型辅助补偿(MAC)旨在将控制误差最小化,使复杂的动态试验能够更快运行。它使用一个实时分析模型,包括降阶试样模型和虚拟试验台,通过共享的高速反射存储器与物理伺服液压试验台同步运行。实现指令力所需的阀门指令由分析模型生成,并在试验台上执行。力和位移信号从试验台返回模型,该过程在每个时钟周期重复进行。