具有最高12kN的动态载荷能力,也可以实现低至几个mN的疲劳测试应用,高效、清洁、低噪声的电动力学测试系统非常适合开展低载荷的疲劳测试。该系统具有直观的系统显示以及可视化测试设置、试验创建、运行和数据处理功能,其先进的系统设计理念确保了试验精度和可靠性。

应用

- 动态力学分析(DMA)

- 拉伸

- 扭转

- 小载荷测试

- 疲劳测试

- 动态特征参数

- 压缩

- 弯曲

- Flex

测试样件

-

聚合物

- 粘弹性材料

- 粘弹性材料

- 塑料

- 聚合物

- 橡胶

- 生物材料与医疗器械

-

复合材料

- 碳纤维

- 陶瓷基

- 复合材料

- 金属基

- 聚合物基

-

陶瓷

- 陶瓷

- 一体式

- 热障镀层

- 消费品与包装

- 微电子

试验标准

- ISO 14801

- ISO 6475

- ASTM F1717

- ASTM F2077

- ISO 7206

- ASTM 1440

- ASTM F543

- ASTM F1800

- ISO 14879

- ASTM F3140-17

- ASTM D7028

- ASTM D5992

- ASTM D5023

- ASTM D5024

- ASTM D5026

- ASTM D5418

- ISO 6721-4

- ISO 6721-5

- ISO 1099

- ASTM 466-96

- ASTM 468-90

- ASTM E606

- ASTM D3479

- ASTM E466

- ASTM E2368

- EUR 22281 EN

- ASTM E647

- ASTM E399

- ASTM E1290

- ASTM E1820

- ASTM 399-17

- ISO 6892

- ASTM D412

- ASTM D882

- ASTM 527-2

- ASTM 527-3

- ISO 7800

- ASTM A938

- ASTM D1043

- ASTM D5279

- ASTM F383

- ISO 5835

- ISO 9268

- ISO 80369-1

- ISO 6721-12

产品主要特点

简捷了当

完全图形化实现系统设置、试验配置、测试创建和运行、系统管理等功能

擘两分星

先进的控制算法实现高精度、可重复的力学测试结果

质效双优

采用自主设计的线性直驱电机作动缸,安静、清洁、高效

推陈出新

性能卓越,具备最高12kN的动态载荷能力,并且可以增配扭转测试附件

产品对比

Acumen 1

- 桌面式系统

- 额定动态载荷:1,250 N (281 lbf)

- 额定静态载荷:1000 N (225 lbf)

- 作动缸动态行程:70 mm (2.75 in)

Acumen 3

- 动态载荷能力: 3000 N (670 lbf)

- 静态载荷能力: 2000 N (450 lbf)

- 作动缸动态行程:70 mm (2.75 in)

- 动态扭转能力:+/- 30 Nm (265 in-lb)

- 静态扭转能力:+/- 21 Nm (185 in-lb)

- 桌面式系统

- 可选标准轴向加载配置或轴扭式复合加载配置

Acumen 12

- 动态载荷能力:12000 N (2697 lbf)

- 静态载荷能力:8500 N (1910 lbf)

- 作动缸动态行程:70 mm (2.75 in)

- 动态扭转能力:+/-120 Nm (1056 in-lb)

- 静态扭转能力:+/- 84.8 Nm (746 in-lb)

- 落地式系统

- 可选标准轴向加载配置或轴扭式复合加载配置

精选案例研究

完整产品信息

|

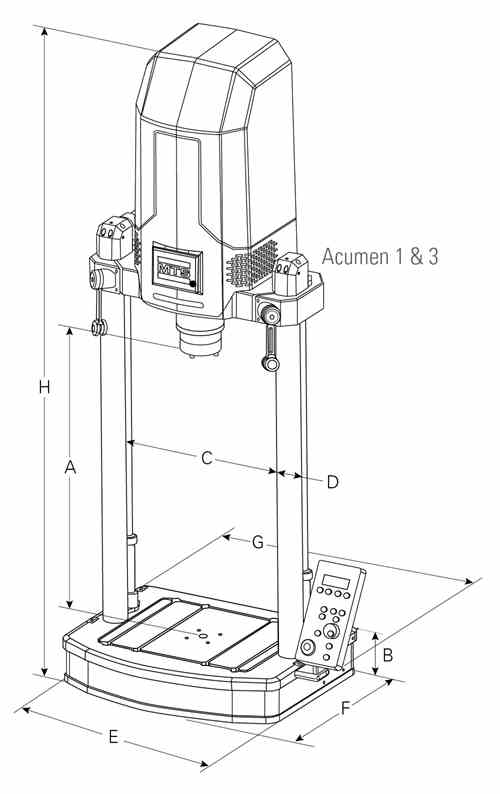

Load Frame Specifications1 |

Diagram Detail |

Acumen 1 G2 |

MODEL Acumen 3 |

Acumen 3 A/T |

|

Dynamic force2 |

|

1250 N (281 lbf) |

3000 N (670 lbf) |

3000 N (670 lbf) |

|

Static force2 |

|

1000 N (225 lbf) |

2000 N (450 lbf) |

2000 N (450 lbf) |

|

Dynamic torque rating |

|

– |

– |

±30 Nm (265 in-lb) |

|

Static torque rating |

|

– |

– |

±21 Nm (185 in-lb) |

|

Actuator dynamic stroke |

|

70 mm (2.75 in) |

70 mm (2.75 in) |

70 mm (2.75 in) |

|

Angular displacement |

|

– |

– |

±135° ±1000 revolutions 0.001 rpm - 350 rpm |

|

Dynamic performance |

|

≤100 Hz |

≤100 Hz |

≤100 Hz |

|

Minimum test space height3 |

A |

26 mm (1.02 in) |

26 mm (1.02 in) |

0 mm (0.00 in) |

|

Maximum test space height4 |

A |

819 mm (32.24 in) |

819 mm (32.24 in) |

603 mm (23.74 in) |

|

Working height5 |

B |

133 mm (5.24 in) |

133 mm (5.24 in) |

133 mm (5.24 in) |

|

Test space width (measured between columns) |

C |

460 mm (18.11 in) |

460 mm (18.11 in) |

460 mm (18.11 in ) |

|

Base plate design |

|

T-Slot (industry standard: 8 mm) |

T-Slot (industry standard: 8 mm) |

T-Slot (industry standard: 8 mm) |

|

Column diameter |

D |

63.5 mm (2.5 in) |

63.5 mm (2.5 in) |

63.5 mm (2.5 in) |

|

Frame footprint width |

E |

634 mm (24.96 in) |

634 mm (24.96 in) |

634 mm (24.96 in) |

|

Frame footprint depth6 |

F |

501 mm (19.72 in) |

501 mm (19.72 in) |

501 mm (19.72 in) |

|

Overall width6 (with frame-mounted controller) |

G |

764 mm (30.08 in) |

764 mm (30.08 in) |

764 mm (30.08 in) |

|

Overall height7 |

H |

1726 mm (67.95 in) |

1726 mm (67.95 in) |

1726 mm (67.95 in) |

|

Weight |

|

188 kg (415 lb) |

188 kg (415 lb) |

230 kg (507 lb) |

|

Noise level - typical8 |

|

47 dB(A) |

47 dB(A) |

47 dB(A) |

|

Noise level - maximum8 |

|

69 dB(A) |

69 dB(A) |

69 dB(A) |

|

Mounting |

|

Tabletop: Vertical |

Tabletop: Vertical |

Tabletop: Vertical |

|

Standard load cell |

|

1.5 kN Accel Comp |

3 kN Accel Comp |

3 kN Accel Comp |

|

Operating temperature |

|

+5C° to +35C° |

+5C° to +35C° |

+5C° to +35C° |

|

Cooling |

|

Automated forced air |

Automated forced air |

Automated forced air |

|

Electrical requirements9 |

Voltage - VAC Frequency - Hz Current - Amps Phase |

100 - 120 (200 - 240) 50 - 60 7 (4) Single |

200 - 240 50 - 60 10 Single |

200 - 240 50 - 60 20 Single |

1. Specifications subject to change without notice.

2. Verifiable with MTS compression spring test. Performance may vary depending on test type, test set-up, frequency, specimen, environment and other factors.

3. Assumes standard system load cell installed, crosshead fully lowered and actuator fully extended to end of the dynamic stroke.

4. Assumes standard system load cell installed, crosshead fully raised and actuator fully retracted to end of the dynamic stroke.

5. From table to top of work surface; without optional isolation pads.

6. For systems with optional test area enclosure, add 98 mm (3.8 in.) to dimension F and 45 mm (1.8 in) to dimension G for overall system dimensions.

7. Measured with crosshead fully raised, without optional isolation pad.

8. Typical usage at 1 m, free field. Noise level varies depending upon test type, specimen, environment and other factors.

9. Acumen 1 current rated at 100 (200) VAC. Acumen 3 current rated at 200 VAC.

|

Load Frame Specifications1 |

Diagram Detail |

MODEL Acumen 12 Acumen 12 A/T |

|

|

Dynamic force2 |

|

12000 N (2697 lbf) |

12000 N (2697 lbf) |

|

Static force2 |

|

8500 N (1910 lbf) |

8500 N (1910 lbf) |

|

Dynamic torque rating |

|

– |

±120 Nm (1056 in-lb) |

|

Static torque rating |

|

– |

±84.8 Nm (746 in-lb) |

|

Actuator dynamic stroke |

|

70 mm (2.75 in) |

70 mm (2.75 in) |

|

Angular displacement |

|

– |

±135° ±500 revolutions 0.001 rpm - 100 rpm |

|

Dynamic performance |

|

≤100 Hz |

≤100 Hz |

|

Minimum test space height3 |

A |

55 mm (2.17 in) |

0 mm (0.00 in) |

|

Maximum test space height4 |

A |

985 mm (38.8 in) |

810 mm (31.9 in) |

|

Working height5 |

B |

815 mm (32.1 in) |

815 mm (32.1 in) |

|

Test space width (measured between columns) |

C |

460 mm (18.11 in ) |

460 mm (18.11 in ) |

|

Base plate design |

|

T-Slot (industry standard: 14 mm) |

T-Slot (industry standard: 14 mm) |

|

Column diameter |

D |

76.2 mm (3 in) |

76.2 mm (3 in) |

|

Frame footprint width |

E |

651 mm (25.6 in) |

651 mm (25.6 in) |

|

Frame footprint depth6 |

F |

817 mm (32.2 in) |

817 mm (32.2 in) |

|

Overall width6 (with frame-mounted controller) |

G |

805 mm (31.7 in) |

805 mm (31.7 in) |

|

Overall height7 |

H |

2810 mm (110.7 in) |

2810 mm (110.7 in) |

|

Weight |

|

953 kg (2100 lb) |

1043 kg (2300 lb) |

|

Noise level - typical8 |

|

62 dB(A) |

62 dB(A) |

|

Noise level - maximum8 |

|

78 dB(A) |

78 dB(A) |

|

Mounting |

|

Floor: Vertical |

Floor: Vertical |

|

Standard load cell |

|

12 kN Accel Comp |

12 kN Accel Comp |

|

Operating temperature |

|

+5C° to +35C° |

+5C° to +35C° |

|

Cooling |

|

Automated forced air & self contained water cooled |

Automated forced air & self contained water cooled |

|

Electrical requirements9 |

Voltage - VAC Frequency - Hz Current - Amps Phase |

200 - 240 50 - 60 38 Single |

200 - 240 50 - 60 38 Single |

1. Specifications subject to change without notice.

2. Verifiable with MTS compression spring test. Performance may vary depending on test type, test set-up, frequency, specimen, environment and other factors.

3. Assumes standard system load cell installed, crosshead fully lowered and actuator fully extended to end of the dynamic stroke.

4. Assumes standard system load cell installed, crosshead fully raised and actuator fully retracted to end of the dynamic stroke.

5. From table to top of work surface; without optional isolation pads.

6. For systems with optional test area enclosure, add 98 mm (3.8 in.) to dimension F and 45 mm (1.8 in) to dimension G for overall system dimensions.

7. Measured with crosshead fully raised, without optional isolation pad.

8. Typical usage at 1 m, free field. Noise level varies depending upon test type, specimen, environment and other factors.

9. Acumen 1 current rated at 100 (200) VAC. Acumen 3 current rated at 200 VAC.

相关产品、附件或备件

需要查找其他产品信息?

前往解决方案查找页面资源