此系统具有 1~1200 kN(220 ~ 270,000 lbf)的测试能力范围,采用了高速响应的低噪声机电伺服驱动和集成式数字闭合回路控制器,确保了整个测试过程中数据的精度与可靠。这些系统久经考验并且易于使用,可提供种类繁多的试验附件满足各种材料和不同形式或标准的测试任务需要。

应用

- 拉伸

- 压缩

- 挠度/弯曲

- 剥离/撕裂

- 剪切

测试样件

- 金属

- 铝合金

- 塑料

- 粘弹性材料

-

复合材料

- 碳纤维

- 陶瓷基

- 复合材料

- 金属基

- 聚合物基

试验标准

- ASTM D3039

- ASTM A48-A48M

- ASTM D3518

- ASTM D412

- ASTM D624

- ASTM D6272

- ASTM D638

- ASTM D695

- ASTM D790

- ASTM D882

- ASTM E21

- ASTM E290

- ASTM E517

- ASTM E646

- ASTM E8-E8M

- ASTM E9

- ISO 10113

- ISO 10275

- ISO 14125

- ISO 6892-1

- ISO 6892-2

- ISO 7438

- ISO 14129

- ISO 178

- ISO 527-2

- ISO 527-3

- ISO 527-4

- ISO 527-5

- ISO 604

- EN 2561

- EN 2562

- EN 2597

- EN 2746

- EN 6031

产品主要特点

精度

先进的 5000 Hz 数据采样率有助于获取更加精确的材料测试数据

性能

紧凑型交流伺服电机驱动器可提供高速、低振动、低噪声测试

简易

支持 TEDS 传感器技术,可自动识别并下载传感器信息

创新

TestSuite TW 软件和自定义测试模板可轻松应对复杂的测试

产品对比

C41 和 C42 型

- 最大额定载荷能力:

- C41.103: 1 kN (220 lbf)

- C42.503: 5 kN (1100 lbf)

- 单立柱

- 桌面型

- 具有标准高度和扩展高度框架可选

C43 型

- 最大额定载荷能力:

- C43.104:10 kN (2200 lbf)

- C43.304: 30 kN (6600 lbf)

- C43.504: 50 kN (11000 lbf)

- 双立柱

- 桌面型

- 具有标准高度和扩展高度框架可选

C44 型

- 最大额定载荷能力:

- C44.304: 30 kN (6600 lbf)

- 双立柱

- 落地式

- 具有标准高度和扩展高度框架可选

C45 型

- 最大额定载荷能力:

- C45.504: 50 kN (11000 lbf)

- C45.105: 100 kN (22500 lbf)

- C45.305: 300 kN (66000 lbf)

- C45.605: 600 kN (132000 lbf)

- C45.126: 1200 kN (270000 lbf)

- 双立柱

- 落地式

- 具有标准高度和扩展高度框架可选

- 可提供加宽框架和多头配置

完整产品信息

MTS CRITERION 系列 40 规格 - 对比

|

|

|

C41型 |

C42型 |

|

C43型 |

|

C44型 |

|

|

|

C41.103 |

C42.503 |

C43.104 |

C43.304 |

C43.504 |

C44.304 |

|

最大额定载荷能力 |

kN lbf |

1 220 |

5 1100 |

10 2200 |

30 6600 |

50 11000 |

30 6600 |

|

可选加载能力 |

N、kN |

1 N, 5 N, 25 N, 50 N, 100 N, 250 N, 500 N, 1 kN |

1 N, 5 N, 10 N, 25 N, 50 N, 100 N, 250 N, 500 N, 1 kN、2 kN、5 kN |

100 N、250 N、 500 N、1 kN、 2.5 kN、5 kN、10 kN |

100 N, 250 N, 500 N, 1 kN、2.5 kN、 5 kN、10 kN、 20 kN、30 kN |

100 N, 250 N, 500 N、 1 kN、 2.5 kN、 5 kN、 10 kN、 20 kN、 30 kN、50 kN |

100 N、250 N、 500 N、1 kN、 2.5 kN、5 kN、 10 kN、20 kN、30 kN、 |

|

|

lbf |

02, 1, 5, 10, 20, 50, 110, 220 |

0.2, 1, 2, 5, 10, 20, 50, 110, 220, 450, 1100 |

20, 50, 110, 220, 500, 1100, 2200 |

20, 50, 110, 220, 500, 1100, 2200 4400, 6600 |

20, 50, 110, 220, 500, 1100, 2200 4400, 6600, 11000 |

20, 50, 110, 220, 500, 1100, 2200 4400, 6600 |

|

框架类型 |

单立柱 桌面型 |

单立柱 桌面型 |

双立柱 桌面型 |

双立柱 桌面型 |

双立柱 桌面型 |

双立柱 落地式 |

|

|

试验空间 |

单 |

单 |

单 |

单 |

单 |

单或双 |

|

|

最大测试速度 |

mm/min in/min |

3000 118 |

2000 78.7 |

2000 78.7 |

1020 40.16 |

750 30 |

1020 40.1 |

|

最小测试速度 |

mm/min in/min |

0.005 0.0002 |

0.005 0.0002 |

0.005 0.0002 |

0.005 0.0002 |

0.005 0.0002 |

0.005 0.0002 |

|

位移分辨率 |

mm in |

0.00005 0.000002 |

0.00005 0.000002 |

0.00005 0.000002 |

0.00006 0.0000024 |

0.00006 0.0000024 |

0.00006 0.0000024 |

|

电源要求 |

V AC

相位 |

200-230 V AC, 5 A, 50 / 60 Hz, 1000 W |

200-230 V AC, 5 A, 50 / 60 Hz, 1000 W 1 |

200-230 V AC, 10 A, 50 / 60 Hz, 2000 W 1 |

200-230 V AC, 12 A, 50 / 60 Hz, 2400 W 1 |

200-230 V AC, 12 A, 50 / 60 Hz, 2400 W 1 |

200-230 V AC, 12 A, 50 / 60 Hz, 2400 W 1 |

|

立柱 |

mm |

100* |

100* |

425 |

420 |

420 |

400 |

|

间距 |

in |

3.94* |

3.94* |

16.73 |

16.54 |

16.54 |

15.75 |

|

垂向测试空间 |

|

|

|

|

|

|

|

|

标准 |

mm in |

1100 43.31 |

820 32.3 |

1200 47.2 |

1200 47.2 |

1200 47.2 |

1190 46.9 |

|

加高 |

mm in |

|

1120 44.1 |

1500 59.1 |

1500 59.1 |

1500 59.1 |

1490 58.7 |

|

横梁行程 |

|

|

|

|

|

|

|

|

标准 |

mm in |

900 35.4 |

650 25.6 |

1000 39.4 |

1000 39.4 |

1000 39.4 |

1000 39.4 |

|

加高 |

mm in |

|

950 37.4 |

1300 51.2 |

1300 51.2 |

1300 51.2 |

1300 51.2 |

|

框架高度 |

|

|

|

|

|

|

|

|

标准 |

mm in |

1520 59.84 |

1332 52.44 |

1616 63.6 |

1752 68.97 |

1752 68.97 |

1951 76.8 |

|

加高 |

mm in |

|

1632 64.25 |

1916 75.43 |

2052 80.78 |

2052 80.78 |

2251 88.6 |

|

框架宽度 |

mm in |

560 22.05 |

704 27.7 |

794 31.3 |

826 32.5 |

826 32.5 |

861 33.9 |

|

框架深度 |

mm in |

530 20.87 |

636 25 |

757 29.8 |

768 30.2 |

768 30.2 |

689 27.1 |

|

框架自重 |

|

|

|

|

|

|

|

|

标准 |

kg lb |

60 132 |

112 246 |

175 385 |

305 671 |

305 671 |

395 869 |

|

加高 |

kg lb |

|

125 275 |

190 418 |

325 715 |

325 715 |

410 902 |

* 对于单立柱载荷框架,该测量值表示夹具中心和立柱盖之间的距离

|

|

|

C45型 |

|||||

|

|

|

C45.504 |

C45.504(宽) |

C45.105 |

C45.305 |

C45.605 |

C45.126 |

|

最大额定载荷能力 |

kN lbf |

50 11000 |

50 11000 |

100 22500 |

300 66000 |

600 132000 |

1200 270000 |

|

可选加载能力 |

N、kN |

1 kN、2.5 kN、 |

1 kN、2.5 kN、 |

1 kN、2.5 kN、 |

150 kN、200 kN、 |

500 kN、600 kN、 |

|

|

|

|

5 kN、10 kN、 |

5 kN、10 kN、 |

5 kN、10 kN、 |

300kN |

|

1000 kN、1200 kN

|

|

|

|

20 kN、30 kN、 |

20 kN、30 kN、 |

20 kN、30 kN、 |

|

|

|

|

|

|

50 kN |

50 kN |

50 kN、100 kN、 |

|

|

|

|

|

lbf |

220, 500, 1100, |

220, 500, 1100, |

220, 500, 1100, |

33000, 44000, |

112400, 132000 |

225000, 270000 |

|

|

|

2200, 4400, |

2200, 4400, |

2200, 4400, 6600, |

66000 |

|

|

|

|

|

6600, 11000 |

6600, 11000 |

11000, 22500 |

|

|

|

|

框架类型 |

双立柱 |

双立柱 |

双立柱 |

双立柱 |

双立柱 |

双立柱 落地式 |

|

|

试验空间 |

单或双 |

单 |

单或双 |

单 |

单 |

单 | |

|

最大测试速度 |

mm/min |

750 |

750 |

750 |

750 |

254 |

254 |

|

|

in/min |

30 |

29.53 |

30 |

30 |

10 |

10 |

|

最小测试速度 |

mm/min |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

|

|

in/min |

0.0002 |

0.0002 |

0.0002 |

0.0002 |

0.0002 |

0.0002 |

|

位移分辨率 |

mm |

0.000047 |

0.000047 |

0.000047 |

0.000049 |

0.000016 |

0.000025 |

|

|

in |

0.0000019 |

0.0000019 |

0.0000019 |

0.0000019 |

0.00000063 |

0.00000098 |

|

电源要求 |

V AC

相位 |

200-230 V AC, 12 A, 50 / 60 Hz, 2400 W 1 |

200-230 V AC, 12 A, 50 / 60 Hz, 2400 W |

200-230 V AC, 22 A, 50 / 60 Hz, 4400 W 1 |

380 - 480 V AC, 20 A, 50 / 60 Hz, 5200 W

3 |

380 - 480 V AC, 20 A, 50 / 60 Hz, 5200 W 3 |

380 - 480 V AC, 20 A, 50 / 60 Hz, 12 kW 3 |

|

立柱 |

mm |

600 |

1000 |

600 |

650 |

750 |

860 |

|

间距 |

in |

23.62 |

39.37 |

23.62 |

25.59 |

29.52 |

33.86 |

|

垂向测试空间 |

|

|

|

|

|

|

|

|

标准 |

mm |

1220 |

1520 |

1220 |

1540 |

2000 |

1800 |

|

|

in |

48.0 |

59.81 |

48.0 |

60.63 |

78.74 |

70.87 |

|

加高 |

mm |

1520 |

|

1520 |

1840 |

|

|

|

|

in |

59.8 |

|

59.8 |

72.44 |

|

|

|

横梁行程 |

|

|

|

|

|

|

|

|

标准 |

mm |

1000 |

1300 |

1000 |

1100 |

1550 |

1500 |

|

|

in |

39.4 |

51.18 |

39.4 |

43.31 |

61.02 |

59.55 |

|

加高 |

mm |

1300 |

|

1300 |

1400 |

|

|

|

|

in |

|

|

51.2 |

55.12 |

|

|

|

框架高度 |

|

|

|

|

|

|

|

|

标准 |

mm |

2265 |

2565 |

2265 |

2585 |

3400 |

3408 |

|

|

in |

89.17 |

100.98 |

89.17 |

101.77 |

133.85 |

134.17 |

|

加高 |

mm |

2565 |

|

2565 |

2885 |

|

|

|

|

in |

100.98 |

|

100.98 |

113.58 |

|

|

|

框架宽度 |

mm |

1316 |

1710 |

1316 |

1365 |

1660 |

1948 |

|

|

in |

51.81 |

67.32 |

51.81 |

53.62 |

65.35 |

76.69 |

|

框架深度 |

mm |

957 |

957 |

957 |

1100 |

1272 |

1669 |

|

|

in |

37.68 |

37.68 |

37.68 |

43.31 |

50.08 |

65.59 |

|

框架自重 |

|

|

|

|

|

|

|

|

标准 |

kg |

1350 |

1700 |

1350 |

1635 |

3500 |

6000 |

|

|

lb |

2970 |

3748 |

2970 |

3605 |

7700 |

13228 |

|

加高 |

kg |

1380 |

|

1380 |

1725 |

|

|

|

|

lb |

3036 |

|

3036 |

3803 |

|

|

MTS CRITERION 系列 40 规格 - 通用

|

薄型载荷值 精确性* (弯曲梁、剪切梁) |

施加载荷的 ± 0.5% |

施加载荷的 ± 1.0% |

|

薄型载荷值范围** (弯曲梁、剪切梁) |

1 至 100% 额定载荷能力 |

0.5% 至 1% 额定载荷能力 |

|

S 梁载荷值精确性* |

施加载荷的 ± 1.0% |

|

|

S 梁载荷值范围** |

1 至 100% 额定载荷能力 |

|

|

最大测试速度下的额定载荷能力 |

100% |

|

|

额定载荷能力下的最大测试速度 |

100% |

|

|

速度测量准确度**** |

C41和C42:设定速度的±0.1% (≥2 mm/min) C43和C44:设定速度的±0.1% (≥1 mm/min) C45:设定速度的±0.1% (≥0.01 mm/min) C45:设定速度的±0.2% (<0.01 mm/min)

|

|

|

位移精度**** |

±0.008mm或设定位移的±0.05%(以较大者为准) |

|

|

应变测量准确度*** |

施加应变的 ± 0.5% |

|

|

安全保护 |

力过载保护、行程限位、过压保护等 |

|

|

载荷过载保护 |

110% |

|

|

数据采集速率 |

最高 5000 Hz |

|

|

控制环路速率 |

5000 Hz |

|

|

环境要求 工作温度

工作湿度 储存温度 最高储存湿度 最高海拔高度 |

5 至 40°C 41 至 104°F 5 至 85% 无冷凝 -18 至 49°C 0 至 120°F 90% 无冷凝 2000 米 |

|

|

电机和驱动系统 |

交流伺服电机 |

|

|

滚珠丝杠 |

预装载 |

|

|

位置测量系统 |

编码器 |

|

|

用户数字输入/输出 (DIO) |

4 个用户数字输入和 4 个用户数字输出 |

|

|

编码器容量 |

4 |

|

* 可提供适用的现场标定服务,以满足 ISO 7500-1、ASTM E4 的要求。

** 范围取决于控制器设置和操作环境。

*** 可提供引伸计标定服务,以满足 ISO 9513、ASTM E83 的要求。

**** 此规格是根据在指定条件和设备下使用 MTS 指定方法进行的测量得出的。如有变更,恕不另行通知。

|

Electromechanical Attachment Specifications |

|

|

|

|

|

|||

|

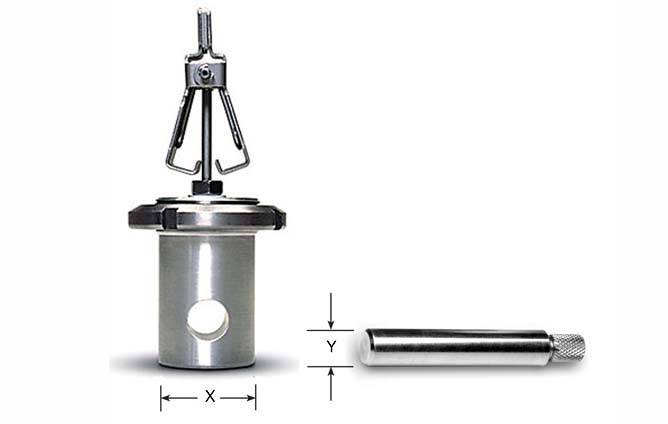

Clevis Pin Connection |

Type B |

Type C (AL) |

Type C (STL) |

Type D |

Type E |

Type F |

Type 20 |

Type 40 |

|

Max. Load Capacity |

10 N |

200 N |

2.5 kN |

150 kN |

300 kN |

600 kN |

30 kN |

100 kN |

|

Clevis Diameter (X) |

12.7 mm (0.50 in) |

15.9 mm (0.625 in) |

15.9 mm (0.625 in) |

31.7 mm (1.25 in) |

60 mm (2.36 in) |

90 mm (3.54 in) |

20 mm (0.787 in) |

40 mm (1.57 in) |

|

Pin Diameter (Y) |

4.7 mm (0.186 in) |

6.4 mm (0.25 in) |

6.4 mm (0.25 in) |

12.7 mm (0.50 in) |

28 mm (1.1 in) |

40 mm (1.57 in) |

10 mm (0.039 in) |

18 mm (0.71 in) |

Pre-packaged Advanced Test Templates for MTS TestSuite TW Software

|

Sample of the many Metals test standards that can be addressed using MTS TestSuite TW templates |

|

| Standard | Description |

|

ASTM E8M |

Standard Test Methods for Tension Testing of Metallic Materials |

|

ISO 6892-1 |

Metallic Materials – Tensile testing at ambient temperature |

|

EN 10002-1 |

Tensile Testing of Metallic Materials |

|

ASTM E9 |

Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature |

|

ASTM E290 |

Standard Test Methods for Bend Testing of Material for Ductility |

|

ISO 7438 |

Metallic Materials – Bend Test |

|

ASTM E21 |

Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials |

|

ISO 783 |

Metallic Materials – Tensile testing at elevated temperature |

|

ASTM E517 |

Standard Test Method for Plastic Strain Ratio r for Sheet Metal |

|

ASTM E646 |

Standard Test Method for Tensile Strain-Hardening Exponents (n-Values) of Metallic Sheet Materials |

|

ASTM A48M |

Standard Specification for Gray Iron Castings |

|

ASTM A370 |

Standard Test Methods for Mechanical Testing of Steel Products |

|

Sample of the many Polymer test standards that can be addressed using MTS TestSuite TW templates |

|

| Standard | Description |

|

ASTM D790 |

Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials |

|

ASTM D412 |

Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers – Tension |

|

ASTM D624 |

Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers |

|

ASTM D638 |

Standard Test Method for Tensile Properties of Plastics |

|

ASTM D695 |

Standard Test Method for Compressive Properties of Rigid Plastics |

|

ISO 178 |

Plastics – Determination of flexural properties |

|

ISO 1798 |

Flexible cellular polymeric materials – Determination of tensile strength and elongation at break |

|

ISO 527 |

Plastics – Determination of tensile properties |

|

ISO 604 |

Plastics – Determination of compressive properties |

|

ASTM D882 |

Standard Test Method for Tensile Properties of Thin Plastic Sheeting |

|

Sample of the many Construction Materials test standards that can be addressed using MTS TestSuite TW templates |

|

| Standard | Description |

|

ASTM A370 |

Tensile Testing & Bend Testing Steel Rebar |

|

ISO 15630 |

Steel for the reinforcement and pre-stressing of concrete – Test methods – Part 1: Reinforcing bars, wire rod and wire |

|

ISO 1920-4 |

Testing of concrete – Part 4: Determination of flexural strength; Determination of tensile splitting strength |

|

ASTM A185/ A185M |

Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete |

|

ASTM A615M |

Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement |

|

ASTM A82/ A82M |

Standard Specification for Steel Wire, Plain, for Concrete Reinforcement |

|

EN 10080 |

Steel for the reinforcement of concrete. Weldable reinforcing steel |

|

ISO 15630-2 |

Steel for the reinforcement and pre-stressing of concrete – Test methods – Part 2: Welded fabric |

|

ASTM F606 |

Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners |

|

Sample of the many Polymer Matrix Composite test standards that can be addressed using MTS TestSuite TW templates |

|

| Standard | Description |

|

ISO 527-4 |

Tensile Properties of Isotropic and Orthotropic Fibre-Reinforced Plastic Composites |

|

ISO 527-5 |

Tensile Properties of Unidirectional Fibre-Reinforced Plastic Composites |

|

ASTM D3039 |

Tensile Properties of Polymer Matrix Composite Materials |

|

ISO 14126 |

In-plane Compressive Properties of Fibre-Reinforced Plastic Composites |

|

ASTM D6641 |

Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture |

|

ISO 14125 |

Flexure Properties of Fibre-Reinforced Plastic Composites |

|

ISO 14129 |

In-Plane Shear Stress/Shear Strain Response of Fibre-Reinforced Plastic Composites |

|

ASTM D3518 |

In-Plane Shear Response of Polymer Matrix Composite Materials |

|

ISO 14130 |

Fibre-Reinforced Plastic Composite – Determination of Apparent Interlaminar Shear Strength by Short-Beam Method |

|

ASTM D2344 |

Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates |

We can provide pre-packaged templates for a wide array of additional materials, including: textiles, paper products, packaging, adhesives, foam, composites and more.

服务与支持

我们的专家随时随地提供帮助,帮助企业正常运转。

相关产品、附件或备件

需要查找其他产品信息?

前往解决方案查找页面立即联系 MTS 业务代表

如您需要报价或需要更多详细信息,我们可随时为您提供帮助。 获取报价资源